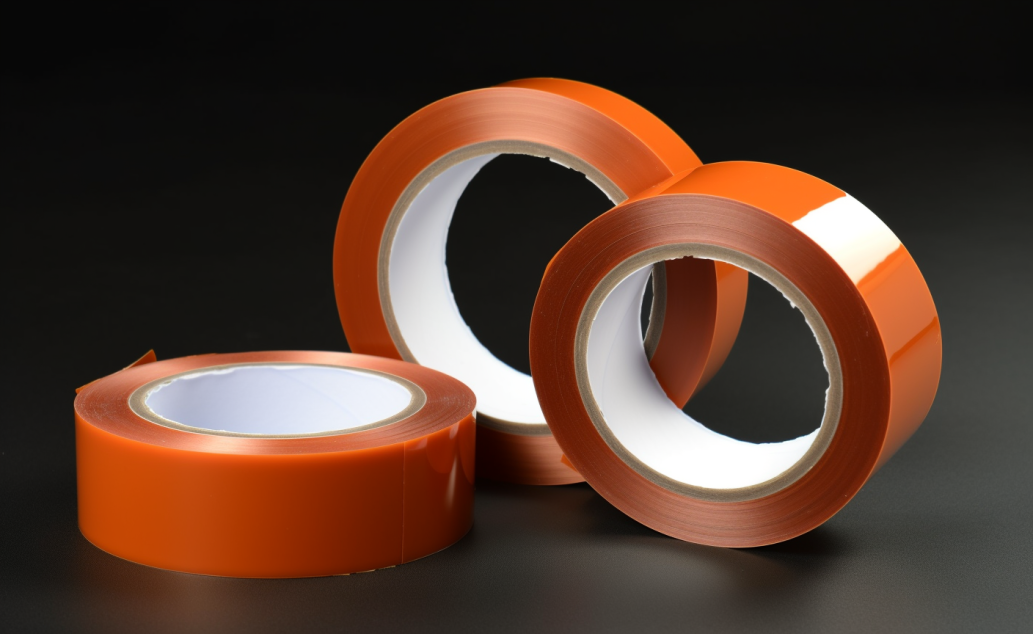

Powder Coat Tape

Powder coating is a popular method of finishing metal surfaces, offering excellent durability and protection against wear and tear. However, to achieve a clean and precise finish, it is important to use the right masking tape that can withstand high temperatures without melting or losing its adhesive properties. In this article, we'll explore the benefits of using high heat tape for powder coating, discuss the different types of heat-resistant masking tape available, and provide some tips for choosing and using these tapes.

The power coat heat tape includes ensuring reliable bonding; avoiding excessive spraying of electronic, solvent, and water-based coatings during the high temperature of the drying process; ensuring that the high temp tape, such as our high heat Teflon tape, for powder coating can be easily removed without residue and avoiding extra work.

What is High Heat Tape for Powder Coating?

High heat tape for powder coating, also known as powder coat heat tape or heat-resistant masking tape, is a type of adhesive tape that can withstand high temperatures without melting or losing its adhesive properties. These tapes are commonly used in powder coating to mask off areas that should not be coated, such as threads, holes, or mating surfaces. By using heat tape for powder coating, you can ensure that the finished product has a clean, precise look, without any unwanted coating on critical surfaces.

How Does Heat Tape Work in Powder Coating?

Heat tape for powder coating, often referred to as heat resistant tape for powder coating or high heat tape for powder coating, plays a crucial role in achieving precise and flawless finishes on coated surfaces. This specialized tape, also known as heat-resistant masking tape for powder coating or powder coat tape, is designed to withstand the intense temperatures involved in the powder coating process.

The fundamental principle behind how heat tape works in powder coating lies in its exceptional ability to endure high temperatures without compromising its integrity. As the powder coating process involves the application of electrostatically charged dry powder onto the target surface, followed by a curing phase at elevated temperatures, heat tape comes into play as a valuable tool for precision masking.

Heat tape's composition combines both durability and heat resistance. It consists of materials that can withstand the extreme heat levels required for curing the powder coating. This tape is strategically applied to specific areas of the object that need to be protected from the powder coat. These could be intricate patterns, precise edges, or designated sections that should remain uncoated.

During the curing process, as the object is exposed to elevated temperatures, the heat-resistant tape for powder coating remains steadfast in its position. It serves as a barrier, preventing the powder-coating material from adhering to the covered areas. The high-temperature tape for powder coating ensures that only the intended sections receive the powder coating treatment, resulting in a precisely defined finish.

Once the curing process is complete and the coated object has cooled down, the heat-resistant masking tape can be carefully removed. A well-designed powder coat tape is engineered to leave minimal to no residue behind and not damage the freshly coated surface. This clean removal is vital to achieving a professional and flawless appearance on the coated object.

Types of Heat-Resistant Masking Tape for Powder Coating

There are several types of high heat tape for powder coating available on the market, each with its own advantages and disadvantages. Here are some of the most common types of heat-resistant masking tape for powder coating:

Polyimide Tape

Polyimide tape, also known as Kapton tape, is a popular choice for high heat masking applications. It can withstand temperatures of up to 500°F and is highly resistant to solvents, chemicals, and abrasion. However, polyimide tape can be quite expensive compared to other types of heat-resistant masking tape.

Polyester tape

Polyester tape is a type of tape commonly used in the powder coating industry to mask off areas that should not be coated. It is a high-temperature tape that can withstand the heat of the curing process used in powder coating, typically up to 400°F (204°C)..Polyester tape is preferred over other types of tape because it does not leave a residue when removed, which is important for achieving a clean finish. It is also resistant to chemicals and solvents, making it ideal for use in harsh environments.

Fiberglass Tape

Fiberglass tape is a cost-effective option for high heat masking applications. It can withstand temperatures of up to 1000°F and is highly resistant to solvents, chemicals, and abrasion. However, fiberglass tape can be quite stiff and difficult to work with, making it less suitable for complex shapes and contours.

Choosing and Using High Heat Tape for Powder Coating

When choosing high heat tape for powder coating, it is important to consider the temperature resistance, adhesion strength, and thickness of the tape. Thicker tapes are usually more durable and provide better protection against the powder coating, but they can also be harder to work with.

It is also important to follow the manufacturer's instructions for proper application and removal to avoid any damage or residue. Before applying the tape, make sure the surface is clean and dry. Apply the tape firmly to ensure good adhesion and avoid any gaps or wrinkles that could allow powder coating to seep underneath.

In conclusion, high heat tape for powder coating is an essential tool for achieving a clean and precise finish. By choosing the right type of heat-resistant masking tape and following proper application and removal procedures, you can ensure that your finished product looks great and offers excellent durability and protection against wear and tear.

Product Inquiry

English

English  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  čeština

čeština  Polska

Polska  Svenska

Svenska  magyar

magyar  Nederland

Nederland