What is Polyimide Heat Resistant Tape and How is it Used

Polyimide heat resistant tape, also known as Kapton tape, helps you protect sensitive components from extreme temperatures and harsh conditions. You often find it in electronics, where it stands up to heat during soldering or circuit board assembly. In 2023, this tape made up 38% of the high-temperature tape market, with electronics holding the largest share at 40%.

Industry | Market Size (2024) | Estimated Size (2033) |

|---|---|---|

Electronics | USD 600 Million | |

Medical Devices | ||

Manufacturing | ||

You also see this tape used in medical devices and manufacturing, thanks to its reliable performance. |

Key Takeaways

Polyimide heat resistant tape, or Kapton tape, protects sensitive components from extreme temperatures, making it essential in electronics and manufacturing.

This tape withstands temperatures up to 500°F (260°C) and maintains its adhesive strength, ensuring reliable performance in high-stress environments.

Use polyimide tape for electrical insulation to prevent short circuits and protect against chemicals, making it ideal for various applications, including medical devices.

When selecting polyimide tape, consider your specific needs, such as temperature resistance and adhesive type, to ensure optimal performance.

Polyimide tape offers long-term value by reducing maintenance costs, as it lasts longer than cheaper alternatives in demanding conditions.

What is Polyimide Heat Resistant Tape

Composition

You find that polyimide heat resistant tape uses a special plastic film called polyimide as its base. This film gives the tape its strength and ability to handle high temperatures. Manufacturers coat one side of the film with a silicone adhesive. This adhesive sticks well to many surfaces and does not break down when exposed to heat.

Polyimide film forms the main layer. It stays stable even when temperatures rise.

Silicone adhesive covers one side. It holds the tape in place and peels off cleanly.

Here is a table that shows the main features of the silicone adhesive used in polyimide heat resistant tape:

Feature | Description |

|---|---|

Type of Adhesive | Silicone adhesive |

Temperature Resistance | Up to 500°F / 260°C |

Adhesion Strength | High tensile strength, 25 oz/in |

Chemical Resistance | Yes, it is both chemical and flame-resistant. |

Additional Properties | Puncture and tear resistant, good electrical properties, peels off cleanly. |

You can see that this combination of polyimide film and silicone adhesive makes the tape strong, flexible, and reliable in tough conditions.

Tip: Silicone adhesives offer excellent thermal stability and leave minimal residue when you remove the tape.

How It Works

Polyimide heat resistant tape works by creating a barrier that protects surfaces from heat, chemicals, and electricity. When you use this tape, the polyimide film stands up to extreme temperatures. It does not melt or lose its shape, even at 500°F (260°C). The silicone adhesive keeps the tape stuck to surfaces, even during rapid temperature changes.

The tape maintains its adhesive properties under extreme heat. It does not break down or lose grip.

The unique structure of polyimide gives the tape thermal stability. It keeps its shape and strength in harsh environments.

Silicone adhesive remains effective during long periods of heat exposure.

Polyimide heat resistant tape also acts as an electrical insulator. The tape has a very high resistivity, which means it does not let electricity pass through. Its breakdown voltage is over 300 kV per millimeter, so it can handle high voltages without failing. This makes it safe to use on circuit boards and electrical wires.

You can rely on polyimide heat resistant tape to:

Protect sensitive parts from heat during soldering or manufacturing.

Insulate electrical components and prevent short circuits.

Guard surfaces against chemicals and flames.

This tape keeps its integrity and adhesive strength, even when you expose it to rapid or extreme temperature changes. You get a dependable solution for many high-temperature and high-stress applications.

Properties

Heat Resistance

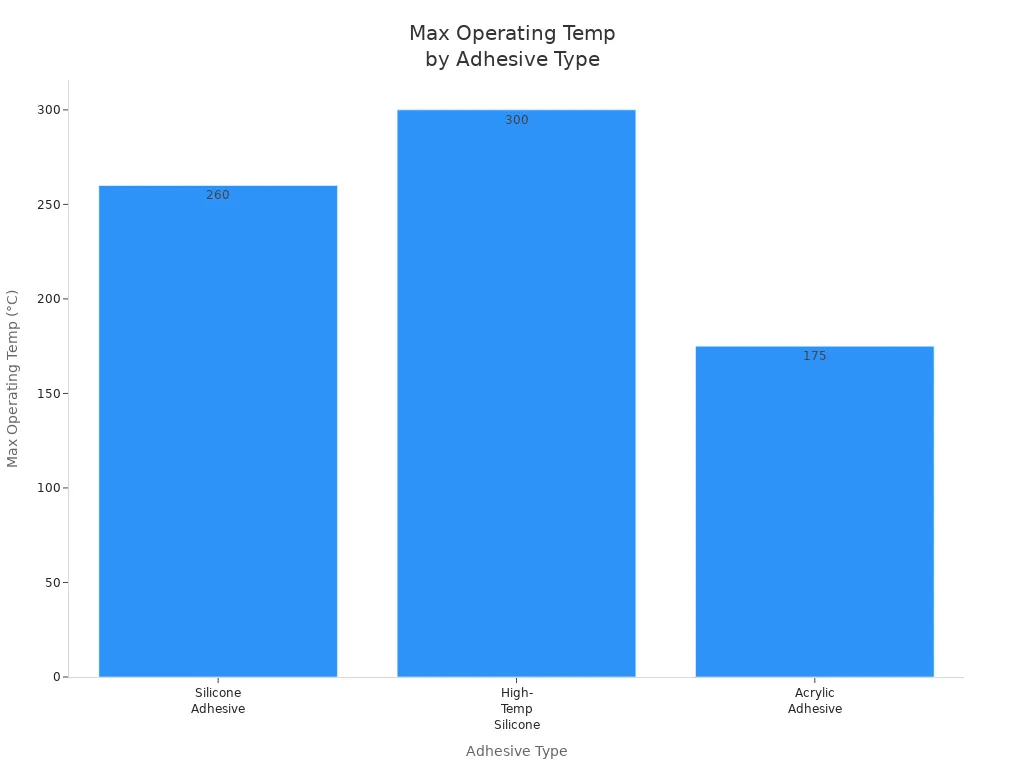

You can trust polyimide heat resistant tape to handle extreme temperatures. This tape works in both hot and cold environments. Most types with silicone adhesive stay strong up to 260°C (500°F). Some high-temperature versions go as high as 300°C (572°F). Even at very low temperatures, down to -73°C (-100°F), the tape remains flexible and reliable. Here is a table that shows the temperature ranges for different adhesives:

Adhesive Type | Maximum Operating Temperature | Minimum Operating Temperature |

|---|---|---|

Silicone Adhesive | 260°C (500°F) | -73°C (-100°F) |

High-Temperature Silicone | 300°C (572°F) | -73°C (-100°F) |

Acrylic Adhesive | 175°C (347°F) | -30°C (-22°F) |

Note: You can use this tape for soldering, powder coating, or any process that needs high heat resistance.

Electrical and Chemical Resistance

Polyimide heat resistant tape gives you excellent electrical insulation. It has a dielectric strength of 7500V, which means it protects against high voltages better than standard PVC tape. You can use it to insulate wires, transformers, motors, and coils. The tape also resists chemicals, so it does not break down when exposed to oils, acids, or solvents. Here is a quick look at its electrical properties:

Feature | Specification |

|---|---|

Dielectric Strength | 7500V |

PVC Tape Comparison | 3000V |

Heat Resistance | No melting at 180°C |

Cold Resistance | No cracking at -40°C |

Applications | Outdoor/industrial use |

This tape keeps your electronics safe, even in harsh or outdoor environments.

Durability

You get strong mechanical durability with polyimide heat resistant tape. The polyimide backing and special adhesives give it high tensile strength and flexibility. You can bend or stretch the tape without tearing it. Many industries, like aerospace and electronics, use this tape because it stands up to stress and heat. Here is a table that shows its performance:

Mechanical Stress Type | Tape Type | Material/Adhesive Composition | Performance/Resistance Details |

|---|---|---|---|

High tensile and mechanical durability | Polyimide (Kapton) tape | Polyimide backing with specialized adhesives | High tensile strength and flexibility; used in aerospace and electronics for mechanical durability under heat. |

You can rely on this tape for long-lasting protection, even in demanding conditions.

Uses

Electronics and Soldering

You often see polyimide heat resistant tape in electronics manufacturing. This tape protects sensitive parts during high-temperature processes. When you work with printed circuit boards, you can use the tape to mask off areas that should not get soldered. It shields gold fingers and connectors from molten solder, preventing damage or oxidation. The tape’s high glass transition temperature, above 350°C, lets it handle the heat from soldering irons and reflow ovens. You can apply the tape precisely over delicate components, which helps you avoid extra cleaning steps after soldering. This process saves time and keeps your devices reliable.

You can use polyimide tape in these ways:

Masking areas on circuit boards during soldering or assembly.

Wrapping wires, transformers, and coils for insulation.

Reinforcing surfaces during spray painting or metal treatments.

Tip: Polyimide tape helps prevent heat-related failures in electronics, making your devices safer and more dependable.

Industrial Applications

In factories and workshops, polyimide heat resistant tape plays a key role in many high-temperature processes. You can use it as a masking tape during powder coating, anodizing, and electroplating. The tape stands up to the heat of curing ovens and protects surfaces from harsh chemicals. It also works well for splicing heat-resistant materials and holding sensors or heater elements in place.

Here is a table showing common industrial uses:

Industry | Application Description |

|---|---|

Powder Coating | Masks off areas to prevent powder from sticking during curing at 160°C–220°C. |

Anodizing | Defines treated zones by masking parts of metal surfaces. |

Electroplating | Prevents unwanted metal deposition, ensuring clean removal. |

Aerospace | Insulates wires, protects insulation blankets, and masks surfaces during treatments. |

Automotive | Insulates wires, provides thermal protection, and masks areas during painting. |

You can rely on this tape to protect surfaces and components in tough industrial settings. Its heat and chemical resistance make it a top choice for many manufacturing steps.

Medical and Sterilization

You also find polyimide heat resistant tape in the medical field. It withstands the high temperatures of autoclaves, which reach 121–134°C for sterilization. The tape does not break down when exposed to ETO gas, so you can use it in many sterilization processes. Its flexibility lets you wrap circuits in implants and wearable sensors. The tape meets strict safety standards, such as USP in vitro tests and ISO 10993-6, showing it is safe for contact with skin and tissues. Long-term studies confirm its stability in implants.

Withstands repeated autoclave cycles.

Remains stable and non-toxic in contact with human tissue.

Supports flexible circuits in advanced medical devices.

Note: Polyimide tape’s biocompatibility and heat resistance make it ideal for medical device manufacturing and sterilization.

Surface Protection

You can use polyimide heat resistant tape to protect surfaces during high-temperature manufacturing. When you perform laser cutting, sandblasting, or high-temperature painting, the tape acts as a shield. It prevents damage from heat, acids, and alkalis. After the process, you can remove the tape easily without leaving sticky residue. This keeps your surfaces clean and undamaged.

In automotive seat heaters, the tape provides both heat and electrical insulation. It endures extreme temperatures, from -269°C to over 400°C, and protects against short circuits. Its mechanical strength helps the tape last through repeated use, keeping seat heaters safe and reliable.

Shields surfaces during laser cutting, painting, and sandblasting.

Protects automotive seat heaters from heat and electrical faults.

Leaves no residue after removal, preserving surface quality.

Polyimide heat resistant tape gives you a simple way to maintain safety and quality in high-temperature environments.

Pros and Cons

Advantages

When you choose polyimide heat resistant tape, you get several important benefits. This tape stands out from other heat-resistant tapes because of its unique features:

High flexibility lets you wrap it around wires, sensors, and odd-shaped parts.

Strong adhesion strength keeps the tape in place, even during high heat.

Excellent heat resistance protects your components from extreme temperatures.

Effective electrical isolation shields sensitive electronics from voltage spikes.

Good optical clarity means you can see through the tape for easy inspection.

You can use this tape in harsh environments. It stays stable and resists tearing or abrasions, even when exposed to temperatures from -269°C to 260°C. Polyimide tape also resists acids, oils, and water, so you can trust it in many settings.

This tape meets the UL510 standard for insulating tape. With a dielectric strength over 4000 V at 1 mil thickness and more than 8000 V at 2 mil, you get reliable protection for your electronics.

While polyimide tape costs more at first, it saves you money over time. For example, using Kapton tape on a high-voltage transformer can save you $600 over 15 years compared to rubber tape. You do not need to replace it as often, so you spend less on maintenance.

Tip: Polyimide tape gives you long-term value and peace of mind in demanding jobs.

Limitations

You should also know about the limits of polyimide heat resistant tape. The table below shows how different adhesives perform:

Adhesive Type | Operating Temperature Range | Limitations |

|---|---|---|

Acrylic | –30°C to 175°C | Brittle at low temperatures, softens at high temps |

Silicone | –73°C to 260°C | Degrades at extreme temperatures (>260°C) |

Polyimide tape with silicone adhesive works well up to 260°C. If you go above this, the adhesive can start to break down. Also, polyimide films are expensive, costing between $300 and $450 per kilogram. Cheaper options like polyester (PET) or polypropylene (PP) tapes exist, but they may not offer the same performance.

Keep in mind: If you need a budget-friendly solution for less demanding jobs, you might want to consider other tapes.

Choosing Tape

Selection Tips

When you choose polyimide heat resistant tape, you want the best fit for your project. Start by thinking about what you need the tape to do. Here are some steps to help you make the right choice:

Identify Your Needs: Decide if you need the tape for electrical insulation, surface protection, or high-temperature masking.

Check Quality and Standards: Look for tapes from manufacturers that follow quality certifications like ISO 9001. This ensures you get a reliable product.

Explore Product Range: Some brands offer many types of polyimide tape. You can find different thicknesses, widths, and adhesive types.

Ask About Customization: Some manufacturers let you customize the tape for special sizes or shapes.

Review Experience and Reputation: Choose a supplier with good reviews and experience in your industry.

Tip: Always match the tape’s properties to your application. For example, thicker tape gives more strength, while a silicone adhesive handles higher heat.

You can also compare technical details. Here is a table with common properties:

Property | Value |

|---|---|

Total Thickness | 127.0 μm |

Adhesive Layer | Acrylic |

Temperature Resistance | 155°C |

Adhesion Strength | 25 oz/in |

Comparison

You may wonder how polyimide tape compares to other high-temperature tapes. Here are some key points:

Polyimide tape can handle up to 300°C for short periods and 180°C for longer use.

Teflon and crepe paper tapes have different heat limits and costs.

The price of polyimide tape depends on the brand, material, and market demand.

You can also see the difference between Kapton tape and other polyimide tapes:

Feature | Other Polyimide Tapes | |

|---|---|---|

Brand | DuPont proprietary | Various manufacturers |

Material | Specific polyimide film | General polyimide |

Thermal Stability | High in extreme conditions | Varies by brand |

Chemical Resistance | Excellent | May vary |

Applications | Aerospace, high-end electronics | Broader uses |

Adhesive | Silicone | Usually silicone, may vary |

You should compare both performance and cost before making your final choice. This helps you get the best value for your needs.

Polyimide heat resistant tape gives you strong protection in high-temperature and demanding environments. You can rely on its heat resistance, electrical insulation, and chemical durability for many tasks. Use it in electronics, manufacturing, or medical settings to keep your projects safe.

Remember: Always match the tape’s features to your specific needs. The right choice helps you get the best results and long-lasting performance.

FAQ

What makes polyimide tape different from regular electrical tape?

Polyimide tape can handle much higher temperatures than regular electrical tape. You can use it in places where heat or chemicals would damage other tapes. It also provides better electrical insulation.

Can you reuse polyimide heat resistant tape?

You should not reuse polyimide tape. The adhesive loses strength after removal. For best results, always use a fresh piece for each application.

Is polyimide tape safe for skin contact?

Yes, most polyimide tapes are safe for brief skin contact. Medical-grade versions pass strict safety tests. If you have sensitive skin, test a small area first.

How do you remove polyimide tape without leaving residue?

You can peel polyimide tape off slowly and evenly. The silicone adhesive usually leaves no sticky residue. If you see any, wipe it away with isopropyl alcohol.

English

English  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  čeština

čeština  Polska

Polska  Svenska

Svenska  magyar

magyar  Nederland

Nederland