Polyimide Tape vs. Green PET Tape for PCB Masking

You want the best results when masking PCBs. Polyimide Tape often works better because it resists high temperatures and harsh chemicals. Tape selection matters a lot in PCB work. The right choice helps protect your circuits and makes your job easier. Think about what your project needs before you pick a tape.

Key Takeaways

Polyimide tape is the best choice for high-temperature PCB masking, handling temperatures up to 280°C without failure.

Green PET tape is cost-effective for low-heat projects, suitable for temperatures up to 205°C, making it ideal for basic masking tasks.

Choose polyimide tape for demanding jobs that require strong chemical resistance and clean removability without residue.

Always match the tape to your project's specific needs, considering factors like temperature, chemical exposure, and budget.

Testing a small piece of tape before full use ensures it adheres well and removes cleanly, preventing potential damage to your PCB.

Quick Recommendation

Best Tape for PCB Masking

You want a tape that protects your PCB during tough processes. Polyimide tape stands out as the best choice for most PCB masking jobs. You get strong protection against heat and chemicals. You also avoid sticky residue after you remove the tape. Polyimide tape works well for high-temperature soldering and reflow processes. You can trust it to keep your circuits safe.

Tip: If you work with simple, low-heat projects, green PET tape can save you money. For most professional or demanding jobs, polyimide tape gives you better results.

Here is a quick comparison to help you decide:

Property | Polyimide (PI) Tape | Green PET Tape |

|---|---|---|

Thermal Stability | Superior | Limited in high-temp |

Mechanical Flexibility | High | Lower |

Durability | Lower (static use) | |

Cost | Higher | More cost-effective |

Best Use | High-performance | Room-temp applications |

Why This Choice

You need to think about what makes a tape work well for PCB masking. Industry experts say material type, adhesive strength, and temperature resistance matter most. Polyimide tape uses a special film that resists heat up to 280°C. You get strong electrical insulation and no sticky mess when you peel it off. Engineers pick polyimide tape because it offers:

High tensile strength

Good chemical resistance

No adhesive residue

Meets ROHS and halogen-free standards

Green PET tape costs less and works for basic masking. It handles moderate heat and some chemicals. You might use it for simple jobs or when you need to save money. Polyimide tape costs more, but you get better protection and cleaner results. You should choose polyimide tape if you want the best masking for your PCB projects.

Tape Comparison

Temperature Resistance

You need to know how each tape handles heat. Polyimide tape stands out for its ability to withstand high temperature. You can use it in soldering and reflow processes where temperature can reach up to 280°C. Green PET tape works well for lower temperature jobs, handling up to 205°C before it starts to degrade. If you use UltraTape UTL 199, you get protection up to 500°F for up to 72 hours. When you mask PCBs, you want a tape that does not fail under extreme temperature. Polyimide tape gives you peace of mind during high temperature cycles. Green PET tape is best for projects where temperature stays moderate. You should always check the temperature rating before you choose a tape. If your process involves repeated temperature spikes, polyimide tape is the safer choice. You avoid damage and keep your circuits protected. Green PET tape saves money, but only if your temperature requirements are low.

Tape Name | Maximum Temperature | Duration |

|---|---|---|

Polyimide Tape | 280°C | Standard use |

Green PET Tape | 205°C | Standard use |

UltraTape UTL 199 | 500°F | Up to 72 hours |

Chemical Resistance

You want your tape to resist chemicals during PCB manufacturing. Polyimide tape shows good chemical stability. It withstands acid, alkali, and organic solvents. Green PET tape also offers good chemical resistance. You can use either tape in environments where chemical exposure is possible. Polyimide tape gives you extra protection if you work with harsh chemicals. Green PET tape works for basic chemical resistance.

Tape Type | Chemical Resistance Description |

|---|---|

Polyimide Tape | Good chemical stability; withstands acid, alkali, organic solvents. |

Green PET Tape | Good chemical resistance. |

Removability

You want a tape that peels off cleanly. Polyimide tape leaves no adhesive residue. You can remove it after high temperature exposure without sticky mess. Green PET tape also removes easily, but sometimes leaves slight residue if exposed to high temperature. You should test removability before using large amounts. Polyimide tape is reliable for clean removal.

Cost

You need to balance performance and budget. Green PET tape costs less per roll. You pay between $0.10 and $0.90 for each roll, with a minimum order of 100 rolls. Polyimide tape costs more, ranging from $0.30 to $0.92 per roll, with a minimum order of 200 rolls. If you need high temperature protection, you pay more for polyimide tape. Green PET tape helps you save money for low temperature jobs.

Tape Type | Price Range (per roll) | Minimum Order |

|---|---|---|

Green PET Tape | $0.10 - $0.90 | 100 rolls |

Polyimide Tape | $0.30 - $0.92 | 200 rolls |

Tip: Always match the tape to your temperature, chemical, and budget needs. You get better results when you choose wisely.

Polyimide Tape

Properties

You want a tape that stands up to tough conditions. Polyimide tape gives you high heat properties and strong protection for your PCB projects. You can rely on its wide temperature range, strong adhesion, and excellent electrical insulation. The table below shows key material properties that make polyimide tape a top choice for masking:

Property | Description |

|---|---|

Temperature Range | -100°F to 500°F (-73°C to 260°C) |

Dielectric Strength | 4.0 kV to 8.5 kV |

Adhesion to Steel | 22 oz./in. width (24 N/100mm) |

Tensile Strength | 33 lbs./in. width (578 N/100mm) |

Thickness Range | 0.05-0.20mm (35μm-180μm) |

You get a tape that works in extreme environments and keeps your circuits safe.

Advantages

Polyimide tape offers several benefits for PCB masking. You can use it in sensitive electronics because it resists heat and chemicals. It also provides strong electrical insulation and stays durable under stress. The table below highlights the main advantages:

Advantage | Description |

|---|---|

Electrical Insulation | Prevents short circuits and protects components |

Heat Resistance | Handles temperatures up to 500°F (260°C) |

Durability | Maintains protection under mechanical and chemical stress |

Chemical Resistance | Shields parts during exposure to corrosive materials |

You avoid sticky residue and get a clean finish after removal. Polyimide tape meets RoHS and halogen-free standards, making it safe for many industries.

Disadvantages

You should know the drawbacks before choosing polyimide tape. The cost is higher than other masking tapes. You may pay more for rolls, especially for large projects. Polyimide tape can be overkill for simple, low-temperature jobs. You need to consider your budget and project needs.

Higher price compared to green PET tape

Not always needed for basic masking tasks

May require custom die-cut masking for complex shapes

Applications

You can use polyimide tape in many demanding environments. It works well for electronic protection and paste, SMT temperature protection, and PCB board gold finger protection. You also see it used for transformers, relays, and high-temperature surface reinforcement. Polyimide tape is recommended for:

Shielding during wave soldering and reflow soldering

Preventing solder contamination on gold fingers and connectors

FPC reinforcement and lamination positioning

Extended high-temperature paint cures

Custom die-cut masking for unique PCB layouts

You get reliable results in consumer electronics, aerospace, and automotive industries. Polyimide tape helps you protect sensitive components and ensures your work stays clean and precise.

Green PET Tape

Properties

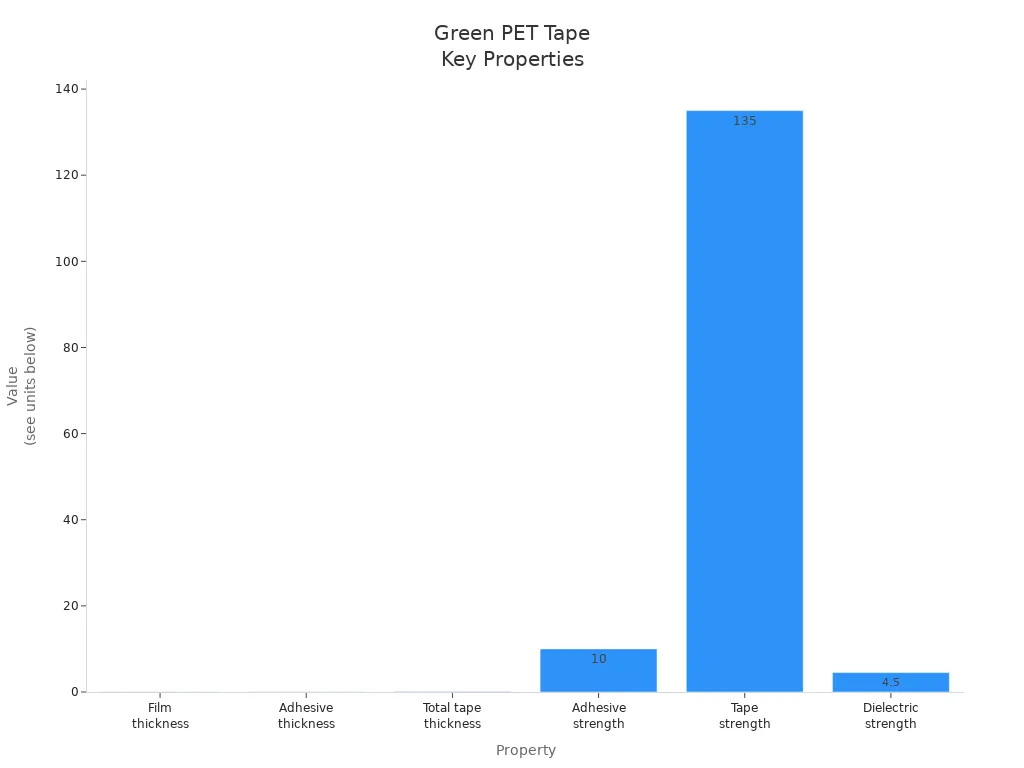

You see green PET tape used often in PCB masking. This tape uses polyester, also called mylar, as its base material. The tape has a green tint, which helps you spot masked areas easily. You get a silicone adhesive that sticks well but peels off cleanly. The total thickness measures about 0.09mm, so you can handle it without trouble. The tape offers good strength and holds up under pressure. You can use it in temperatures from -20°C to 204°C. The dielectric strength reaches 4.5 kV, so you get solid electrical insulation.

Property | Description |

|---|---|

Tape material | PET – polyester (mylar) |

Colour | Green tinted |

Adhesive | Silicone adhesive |

Film thickness | 0.05mm |

Adhesive thickness | 0.04mm |

Total tape thickness | 0.09mm |

Adhesive strength | 10N / 25mm |

Tape strength | 135 kPa |

Dielectric strength | 4.5 kV |

Use temperature range | -20 to +204 °C |

Advantages

You get several benefits when you choose green PET tape. The tape resists solvents and chemicals, so you can use it in many PCB processes. The green color makes it easy to see where you placed the tape. You find that the tape is translucent, which helps you check alignment without removing it. The silicone adhesive works well at high temperatures and peels off without leaving much residue. You save money because green PET tape costs less than polyimide tape. You can cut and apply it quickly, which makes your job easier.

Tip: Use green PET tape for powder coating, anodizing, and basic PCB masking. You get reliable results without spending too much.

Disadvantages

You need to know the limits of green PET tape. The tape does not handle extreme heat as well as polyimide tape. If you use it above 204°C, you risk adhesive breakdown or tape failure. The tape may leave slight residue if exposed to high temperatures for a long time. You should avoid using green PET tape for very demanding or sensitive PCB jobs. The tape works best for simple masking tasks.

Limited high-temperature resistance

Possible residue after long heat exposure

Not ideal for complex or critical PCB masking

Applications

You use green PET tape in less demanding PCB masking jobs. The tape works well for wave soldering, powder coating, and anodizing. You can mask gold fingers and connectors during assembly. The tape helps you protect areas from solder or chemicals. You see green PET tape used in electronics, automotive, and appliance manufacturing. You can also use green polyester masking tape for electrical insulation and surface protection. The tape gives you a cost-effective solution for everyday PCB work.

Application | Benefit |

|---|---|

PCB masking for wave soldering | Protects gold fingers |

Powder coating and anodizing | Resists chemicals and solvents |

Electrical insulation | Provides dielectric strength |

Surface protection | Easy to apply and remove |

High-Temperature Masking Options

Choosing the Right Tape

You want the best results when working with high-temperature masking tape. Picking the right tape protects your PCB and keeps your process smooth. You need to look at several important factors before you decide. The table below shows what you should check when you choose a heat-resistant tape for your project:

Factor | Description |

|---|---|

Temperature Resistance | The tape should withstand the specific temperature range of the application without failure. |

Adhesive Strength | Strong adhesive is necessary to ensure the tape adheres well to various surfaces under high heat. |

Residue-Free Removal | The tape must be removable without leaving residue that could damage sensitive surfaces. |

Standards and Certifications | Ensure the tape meets quality standards like ISO 9001:2015 and ASTM D6123-07 for reliability. |

Size and Customization Options | Consider the dimensions and whether custom sizes are needed for specific applications. |

Durability Factors | The tape should be durable enough to withstand harsh environments and prolonged exposure to heat. |

You should always match the tape’s temperature rating to your process. Polyimide tape works as a high-temperature masking tape for soldering and reflow. Green PET tape fits better for lower heat jobs. Both tapes offer strong adhesive strength, but polyimide tape often holds up better during high-heat cycles. You want a tape that removes cleanly without leaving unwanted residue. Polyimide tape excels here, even after long exposure to heat.

If you need powder coating masking tapes, check if the tape meets industry standards. Some jobs require custom sizes or shapes. You can order both polyimide and PET tapes in different widths and lengths. Durability matters, too. High-performance heat-resistant tape will last longer and protect your PCB during tough processes.

Tip: Always test a small piece of tape before full use. This helps you see if the tape sticks well and peels off cleanly.

Project Requirements

You need to think about your project’s needs before you pick a high-temp tape. Each job has different requirements. Here are some points to help you decide:

Temperature Resistance: Use polyimide tape for high-temperature jobs like soldering or reflow. This high-temp tape can handle up to 280°C. Green PET tape works for jobs up to 205°C. If your process gets hotter, always choose a high-temperature heat-resistant tape.

Chemical Resistance: If your project uses harsh chemicals, polyimide tape gives better protection. It resists acids, alkalis, and solvents. Green PET tape works for basic chemical exposure but may not last as long in tough environments.

Removability: You want a tape that peels off easily. Polyimide tape removes cleanly, even after high heat. Green PET tape can leave a little residue if you use it above its rated temperature.

Budget Considerations: Green PET tape costs less. It works well for simple masking or when you need many rolls. Polyimide tape costs more, but it lasts longer and protects better. Over time, high-temp tape can save money by reducing rework and damage.

Application Type: For powder coating masking tapes, both options work. Polyimide tape gives better results for high-heat-resistant tape needs. Green PET tape fits basic powder coating jobs.

You should always match the tape to your project. If you need high-temp tape for demanding jobs, polyimide tape is the best choice. For simple masking, green PET tape saves money and works well. High-temperature masking options give you flexibility for many PCB tasks.

Note: Always check if your tape meets industry standards. This ensures safety and quality for your finished product.

You can use heat-resistant tape for many jobs. Polyimide tape is a high-performance heat-resistant tape. It works for soldering, reflow, and harsh chemical exposure. Green PET tape is a good choice for less demanding jobs. Both tapes serve as powder coating masking tapes, but you should pick the one that matches your temperature and chemical needs.

When you choose a high-temp tape, think about temperature, chemicals, removability, and cost. You get the best results when you match the tape to your project.

You now know that polyimide tape gives you high thermal resistance and chemical stability, making it ideal for demanding PCB jobs. Green PET tape works well for moderate temperatures and general insulation. Before you choose, review practical factors:

Temperature ratings for your process

Adhesive type and residue concerns

Tape thickness and mechanical protection

Supplier reliability and test data

If you want more details, explore these resources:

Test both tapes in your process to find the best fit for your needs.

FAQ

What is PCB masking and why do you need it?

PCB masking protects specific areas of your circuit board during manufacturing. You use masking to keep solder, chemicals, or paint off sensitive parts. This step helps you avoid damage and ensures your board works as designed.

How do you choose between polyimide tape and green PET tape for masking?

You look at your process temperature, chemical exposure, and budget. Polyimide tape works best for high-temperature masking. Green PET tape fits basic masking jobs. You match the tape to your needs for the best results.

Can masking tape leave residue on your PCB?

You want clean removal after masking. Polyimide tape usually peels off without residue. Green PET tape may leave a little residue if you use it above its rated temperature. Always test masking tape before using it on your whole board.

Is masking important for wave soldering and reflow processes?

You need masking for wave soldering and reflow. Masking keeps solder off gold fingers and connectors. You protect critical areas and improve the quality of your finished PCB. Good masking helps you avoid costly repairs.

How does masking affect PCB quality and reliability?

Masking prevents unwanted material from reaching sensitive spots. You get better insulation and protection. Proper masking reduces defects and increases the lifespan of your PCB. You should always use masking for reliable results.

English

English  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  čeština

čeština  Polska

Polska  Svenska

Svenska  magyar

magyar  Nederland

Nederland