What Is High Temperature Resistance Adhesive Tape and How Does It Work

You use high temperature resistance adhesive tape when you need something to hold strong in hot conditions. This tape can handle heat from 120 to 300 degrees Celsius, making it ideal for tough jobs in factories and workshops. Unlike regular tape, which melts or loses grip with heat, this tape uses special materials like polyimide or PET film and strong adhesives such as silicone or acrylic. You will find it more expensive than regular tape, but it gives you reliable performance where ordinary tapes fail.

Key Takeaways

High temperature resistance adhesive tape can withstand heat from 120 to 300 degrees Celsius, making it ideal for tough jobs in factories and workshops.

This tape uses special materials like polyimide and strong adhesives, ensuring it maintains grip and does not melt or break down under heat.

Common applications include masking during plating, insulating wires in electronics, and protecting parts in automotive and aerospace industries.

Always check the tape's temperature rating and material type to ensure it meets your project's specific heat requirements.

Using the right high temperature resistance adhesive tape enhances safety, reliability, and efficiency in various industrial and DIY applications.

High Temperature Resistance Adhesive Tape Overview

Definition & Purpose

You use high temperature resistance adhesive tape when you need a tape that can handle extreme heat without losing its grip or breaking down. This special tape works in places where regular tape would melt, burn, or leave a sticky mess. You often see it in factories, workshops, and even in your home if you work with electronics or appliances that get hot.

The main purpose of high temperature resistance adhesive tape is to protect, insulate, and hold materials together during processes that involve high heat. You might use it to mask off areas during metal plating, keep parts together in car engines, or wrap wires in electronics to prevent overheating. In many industries, this tape helps keep things safe and running smoothly.

Did you know?

High temperature resistance adhesive tape is essential for safety and efficiency in many industries. It helps prevent mistakes, protects workers, and keeps equipment safe from heat damage.

Here are some common uses for this tape in different industries:

Masking parts during plating or powder coating

Insulating wires and components in electronics

Protecting parts in automotive and aerospace manufacturing

Sealing and insulating HVAC systems in construction

Packaging food that needs to be cooked or sterilized

You also find that these tapes help save energy by keeping heat where it belongs, especially in heating and cooling systems.

Key Differences from Standard Tape

You might wonder how high temperature resistance adhesive tape stands apart from regular tape. The answer lies in its materials and performance. While standard tape works for everyday tasks, it cannot handle high heat or harsh chemicals.

Here is a table that shows the main differences:

Characteristic | High-Temperature Tape | Standard Adhesive Tape |

|---|---|---|

Temperature Resistance | Above 150°C | Typically below 150°C |

Backing Materials | Polyester, glass cloth, Kapton, aluminum | Various, often not heat-resistant |

Applications | Masking, protection in high heat environments | General bonding and sealing |

Adhesive Types | Thermosetting rubber, acrylic, silicone | Common adhesives without heat resistance |

You will notice that high temperature resistance adhesive tape uses special backings like polyimide (Kapton), glass cloth, or aluminum. These materials can handle much higher temperatures than the paper or plastic found in regular tape. The adhesives in these tapes also stay sticky and strong, even when exposed to heat, chemicals, or moisture.

Another big difference is how the tape performs under stress. High temperature resistance adhesive tape keeps its grip, resists chemicals, and often comes off cleanly without leaving sticky residue. Standard tape may lose its stickiness, break down, or leave a mess when exposed to heat or harsh conditions.

When you need a tape that will not fail in tough environments, you should choose high temperature resistance adhesive tape. It gives you peace of mind and reliable performance where regular tape cannot compete.

How High Temperature Resistance Adhesive Tape Works

Material Composition

You might wonder why some tapes can handle extreme heat while others fail. The answer starts with the materials used to make them. High temperature resistance adhesive tape uses special base materials that can stand up to high temperatures without breaking down or losing strength.

Here is a table that shows some common materials and their properties:

Property | Description |

|---|---|

Material Composition | Polyimide film |

High Temperature Resistance | |

Chemical Resistance | Resists solvents, oils, and acids |

Dielectric Strength | Excellent electrical insulator |

Flexibility | Can conform to irregular surfaces |

UL Recognition | Meets flammability standards |

Polyimide film is one of the most popular choices. You see it in many high temperature resistance adhesive tapes because it can handle heat up to 260°C (500°F). It also resists chemicals and acts as a strong electrical insulator. This makes it useful in electronics, automotive, and industrial settings.

Other materials include polyester, glass cloth, and Teflon-coated glass fiber. Each material offers different levels of heat resistance. Take a look at this comparison:

Type of Tape | Base Material | Temperature Resistance |

|---|---|---|

PET high-temperature tape | Polyester film coated with silicone | 356°F-392°F (180-200°C) |

Teflon glass cloth high-temperature tape | Glass fiber cloth coated with Teflon | |

PI (polyimide) heat resistant tape | Polyimide film coated with silicone | Up to 260°C (long-term) |

Glass cloth tape | Glass cloth coated with silicone | Excellent high temperature resistance |

You can see that polyimide and glass cloth tapes offer the highest temperature resistance. Polyester tapes work well for medium heat but not for the hottest jobs. When you choose a tape, always check the base material to match your needs.

Tip:

Always match the tape material to your project’s temperature range. Using the wrong material can lead to tape failure and possible damage.

Adhesive Properties

The adhesive is just as important as the backing material. You need an adhesive that stays sticky and strong, even when exposed to high heat. Most high temperature resistance adhesive tapes use silicone or acrylic adhesives. Silicone adhesives work best for extreme temperatures. They keep their grip from very low to very high temperatures and resist chemicals and moisture. Acrylic adhesives handle moderate heat and offer good bonding strength.

You should also know about continuous and peak temperature resistance. Continuous temperature resistance means the tape can handle a certain temperature for a long time without losing its properties. Peak temperature resistance is the highest temperature the tape can survive for a short period.

Here is a table that shows the difference:

TAPE BACKING TYPES | CONTINUOUS | PEAK |

|---|---|---|

Polyester | 130°C | 200°C |

3M 8902 | 177°C | 218°C |

If you use the tape in a process that stays hot for hours, you need to look at the continuous temperature rating. If you only need the tape to survive a quick burst of heat, the peak rating is more important.

Note:

Always check both continuous and peak temperature ratings before you choose a tape. This helps you avoid tape failure during your project.

The right combination of backing material and adhesive lets high temperature resistance adhesive tape perform in places where regular tape would melt or lose its grip. You get reliable performance, safety, and peace of mind when you use the right tape for the job.

Types of High Temperature Resistance Adhesive Tape

When you choose a high temperature resistance adhesive tape, you will find several types, each with unique features and uses. Here are the main categories you will see in the market:

Silicone Adhesives

Kapton (Polyimide) Tape

Foils

Glass Cloth

Polyester (PET) Film Tape

VHB Tape

Acrylic Adhesives

Polyimide Tape

Polyimide tape, often called Kapton tape, stands out for its ability to handle extreme heat. You can use it in temperatures from -269°C up to 260°C (or -452°F to 500°F). Some special versions go as high as 300°C (572°F). This tape works well for electrical insulation, coil and magnetic wire wrapping, and masking printed circuit boards during soldering.

Applications | |

|---|---|

Electrical insulation, coil wrapping, PCB masking, powder coating | |

High-temp masking, aerospace, advanced electronics |

Tip: Polyimide tape leaves no sticky residue after removal, making cleanup easy.

Silicone-Based Tape

Silicone-based tapes offer strong performance in hot environments. You can use them up to 177°C (350°F). These tapes bond well to many surfaces and resist chemicals and moisture.

Automotive: Heat shields and gaskets

Electronics: Heat sinks and display panels

Aerospace: Sealing panels and insulation

Industrial: Glass manufacturing and metal fabrication

Industry | Common Uses |

|---|---|

Automotive | Heat shields, gaskets, insulation in engines |

Electronics | Heat sinks, thermal management, display panels |

Aerospace | Sealing aircraft panels, gaskets, insulation |

Industrial | Glass manufacturing, metal fabrication, power generation |

Glass Cloth Tape

Glass cloth tape gives you excellent strength and heat resistance. It can handle continuous temperatures up to 260°C (500°F). The woven glass cloth backing makes it strong and durable.

Offers strong electrical insulation

Withstands abrasion, chemicals, and solvents

Removes cleanly without residue

Maintains shape and strength at high temperatures

Other Types

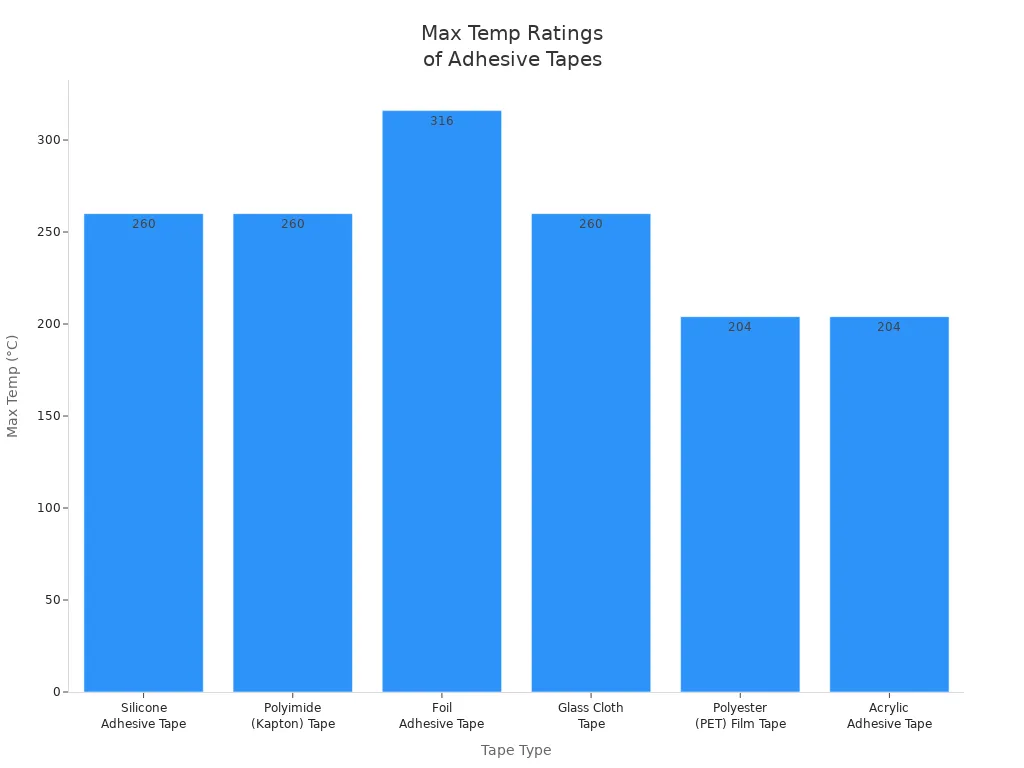

You will also find other tapes for special needs. These include foil tapes, PET film tapes, and acrylic adhesive tapes. Each type has its own temperature range and best uses.

Type of Tape | Temperature Range |

|---|---|

Silicone Adhesive Tape | -60°F to 500°F (-51°C to 260°C) |

Polyimide (Kapton) Tape | -103°F to 500°F (-75°C to 260°C) |

Foil Adhesive Tape | -65°F to 600°F (-54°C to 316°C) |

Glass Cloth Tape | 500°F (260°C) |

Polyester (PET) Film Tape | -94°F to 400°F (-70°C to 204°C) |

Acrylic Adhesive Tape | -40°F to 400°F (-40°C to 204°C) |

Note: Always check the temperature range before you pick a tape for your project.

Features & Benefits

Temperature Range & Performance

You need a tape that performs well in hot environments. High temperature resistance adhesive tape gives you a wide temperature range, so you can use it for many jobs. Some tapes work at 200°C for long periods and can handle up to 260°C for short bursts. You get strong adhesion that does not leave residue when you remove the tape. This clean removal helps you keep your workspace tidy.

Property | Description |

|---|---|

Thermal Stability | Operates at 200°C for long periods, up to 260°C peak |

Adhesion Resistance | Stays strong, leaves no residue after removal |

Mechanical Strength | Handles tight wrapping and heavy use |

Tip: Always check the tape’s temperature rating before you start your project.

Durability & Chemical Resistance

You want a tape that lasts in tough conditions. These tapes use strong base materials like PET, polyimide film, glass cloth, and Teflon fiber. You get good resistance to chemicals, so the tape works well in factories and workshops. The adhesive layer uses acrylic, silica gel, or silicon rubber, which keeps the tape bonded even when exposed to heat and chemicals.

Factor | Description |

|---|---|

Chemical Resistance | Stands up to solvents, oils, and acids |

Environmental Conditions | Resists mechanical stress and harsh environments |

Anti-Corrosion | Silicone rubber coated glass fiber cloth prevents corrosion |

You can rely on the tape to keep working, even when exposed to chemicals or rough handling.

Safety & Reliability

You need safety and reliability for critical jobs. Many tapes meet strict safety standards like UL94 V-2 for flame resistance and Federal Aviation Regulation 25.853 for aerospace use. You get peace of mind knowing the tape will not fail in important applications.

Certification | Description |

|---|---|

UL94 V-2 | Flame resistance standard |

Federal Aviation Regulation 25.853 | Aerospace safety and compliance |

Environmental resistance

Adhesive strength

Wide temperature range

Conformability to different surfaces

Note: Reliable tape helps protect equipment and keeps workers safe.

Applications

Industrial Uses

You often see high temperature resistance adhesive tape in factories and workshops. You can use it to mask surfaces during powder coating or metal plating. This tape protects parts from heat and chemicals. Workers also use it to bundle wires, seal ducts, and insulate machinery. The tape’s strength and heat resistance help keep equipment running safely.

Electronics & Electrical

You need reliable tape when working with electronics. High temperature resistance adhesive tape insulates wires and protects circuit boards during soldering. You can wrap coils, secure sensors, and shield delicate parts from heat. The tape’s clean removal means you avoid sticky residue on sensitive components. Many electronics makers trust this tape for its electrical insulation and durability.

Automotive & Aerospace

You face tough conditions in automotive and aerospace work. Engines, exhaust systems, and aircraft parts get very hot. You must choose the right tape for each job. Here are some steps to help you select the best tape:

Analyze your engine compartment environment.

Determine tape material and adhesive needs.

Consider extra features like flame resistance or flexibility.

Calculate how much tape you need.

Store the tape in a cool, dry place.

Apply the tape carefully to clean surfaces.

Test the tape for performance.

Monitor and review the tape’s condition over time.

You should also think about the temperatures the tape will face. Some tapes work better at higher temperatures. Make sure the tape can fit around different shapes and surfaces. If you need to print labels on the tape, check if the material supports printing.

Tip: Always test the tape in your specific environment before using it on important parts.

Home & DIY

You can use this tape at home for small repairs and creative projects. It works well for fixing appliances, wrapping cables, or protecting surfaces from heat. If you enjoy crafts or model building, you will find the tape easy to cut and shape. Its clean removal makes it a favorite for temporary fixes and DIY experiments.

You now know that high temperature resistance adhesive tape stands out for its strength and reliability in hot conditions. You can use it in factories, electronics, cars, and even at home. Each type of tape works best at certain temperatures. Always check the temperature rating before you choose. When you match the right tape to your project, you get safe and lasting results.

Remember: The right tape keeps your work safe and your equipment protected.

FAQ

What makes high temperature resistance adhesive tape different from regular tape?

You get special materials and adhesives in high temperature resistance tape. These let the tape handle much higher heat without melting or losing grip. Regular tape cannot do this.

Can you use high temperature resistance adhesive tape outdoors?

Yes, you can use it outdoors. Many types resist sunlight, moisture, and temperature changes. Always check the product label for outdoor use.

How do you remove high temperature resistance adhesive tape without leaving residue?

You should peel the tape slowly and evenly. Most high temperature tapes come off cleanly. If any residue remains, you can wipe it away with rubbing alcohol.

What industries use high temperature resistance adhesive tape the most?

You find this tape in electronics, automotive, aerospace, and manufacturing. Workers use it for insulation, masking, and protecting parts from heat.

Can you cut high temperature resistance adhesive tape to size?

Yes, you can cut it with scissors or a utility knife. Always use clean, sharp tools for the best results.

English

English  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  čeština

čeština  Polska

Polska  Svenska

Svenska  magyar

magyar  Nederland

Nederland