Top 7 High Temperature Masking Tapes for 2025

Looking for the best high temperature masking tape for your next project? Here are the top picks for 2025:

3M

Nitto Denko

Tesa SE

EQUTY BAYMERS

Craft Express

Joto Heat Tape

Green Poly Tape for Powder Coating

You get strong adhesive power and heat resistance from these brands. They handle tough jobs in automotive, aerospace, electronics, and manufacturing. Most tapes work in temperatures from 250°F up to 500°F. Companies like 3M and Tesa SE lead the market with new ideas and a focus on sustainability.

Key Takeaways

Choose high temperature masking tapes that can withstand temperatures from 250°F to 600°F for various projects.

Look for tapes with strong adhesive properties that peel off cleanly to save time on cleanup.

Consider eco-friendly options like Tesa SE, which uses recycled materials and a solvent-free process.

Evaluate the tape's application versatility; many tapes work well in automotive, electronics, and crafting.

Always clean the surface before applying tape to ensure the best adhesion and performance.

Top 7 High Temperature Masking Tapes

3M High Temperature Masking Tape

You probably know 3M as a leader in tape technology. Their high temperature masking tape stands out for its reliability and performance. If you need a tape that can handle tough jobs, 3M gives you options for different needs. Here’s a quick look at two popular choices:

Product Name | Maximum Temperature Resistance | Adhesive Strength |

|---|---|---|

Scotch® High Temperature Masking Tape 214 | Moderate adhesion with high heat resistance | |

3M™ Specialty High Temperature Masking Tape 501+ | 300°F / 150°C | Strong holding for critical paint masking applications |

You can trust 3M tapes for automotive painting, powder coating, and other high-heat jobs. They peel off cleanly and keep sharp paint lines. If you want a high temperature masking tape that works every time, 3M is a safe bet.

Nitto Denko Specialty Tape

Nitto Denko brings Japanese innovation to the world of high temperature masking tape. You get a wide range of products and strong global support. Many users like Nitto Denko for its weather resistance and flexibility. Here’s what makes it special:

Nitto Denko offers a huge selection of tapes for different industries.

The company has a strong global network, so you can find their tapes in many countries.

Let’s see what users say:

Advantages | Disadvantages |

|---|---|

Superior weather resistance; keeps elasticity in humid or cold conditions. | Limited availability in some regions. |

Excellent electrical and mechanical strength. | Some types may have lower temperature ratings than 3M. |

Smooth unwind and easy tear by hand. | N/A |

If you need a high temperature masking tape that works in tough weather or on electrical projects, Nitto Denko is a smart choice.

Tesa SE Eco-Friendly Masking Tape

Tesa SE gives you a high temperature masking tape that is both strong and eco-friendly. This tape uses bio-based or recycled materials and a solvent-free process. You help the planet while getting great results. Here’s what sets Tesa SE apart:

Sustainability Aspect | Description |

|---|---|

Bio-based Carbon Content | 98% bio-based carbon content, certified by DIN CERTCO and TÜV AUSTRIA |

Production Process | Solvent-free |

PCR PET Content | 90% PCR PET in backing, recycling-friendly (INGEDE Method 12) |

Recycled PET Content | Over 85% recycled PET in backing |

Paper Backing | FSC®-certified, recycling-friendly paper |

Tip: If you want to reduce your environmental impact, Tesa SE’s eco-friendly tape is a great pick for your next project.

EQUTY BAYMERS Heat Resistant Tape

EQUTY BAYMERS gives you a high temperature masking tape that can handle serious heat. This tape works up to 482°F, so you can use it for powder coating, soldering, or other hot jobs. It holds up well even after lots of use.

The tape is known for its toughness and durability.

You can count on EQUTY BAYMERS when you need a tape that won’t quit under pressure.

Craft Express High Temp Tape

Craft Express makes high temperature masking tape for crafters and pros alike. This tape is perfect for heat presses, irons, and other hot tools. It sticks well, holds transfers in place, and peels off cleanly. Here’s a quick look:

Feature | Description |

|---|---|

Heat Resistance | |

Adhesive Strength | Extra-strong, heat-resistant adhesive |

Residue | Leaves no sticky mess |

Size | 1 roll, 1 in x 33 ft (2.5 cm x 10.1 m) |

Compatibility | Works with Cricut Hat Press™, irons, and most heat presses |

You get a tape that makes crafting easy and mess-free. If you love DIY projects, Craft Express is a handy choice.

Joto Heat Tape

Joto Heat Tape is a favorite for sublimation and heat transfer projects. You get good sticking power and easy removal. Most users say it leaves no residue, but some mention it can discolor at very high temperatures. Here’s what people like and dislike:

Pros | Cons |

|---|---|

Sticks well without residue | Not very sticky for sublimation prints |

No residue on patches | May leave residue or discoloration |

Good adhesion on many surfaces | Some brands may discolor at high heat |

If you want a high temperature masking tape for crafts or heat transfers, Joto is a solid pick.

Green Poly Tape for Powder Coating

Green Poly Tape is the go-to high temperature masking tape for powder coating. You get a tape that resists heat, chemicals, and abrasion. It keeps sharp lines and peels off cleanly after baking. Many shops use it for coating metal parts, painting, and even electronics.

Note: Green Poly Tape is a must-have if you work with powder coating ovens or need a tape that stands up to harsh conditions.

You can rely on these seven tapes for your toughest jobs. Each one brings something special, whether you want eco-friendly materials, extra heat resistance, or easy removal.

Why These Tapes Lead the Market

Temperature Resistance

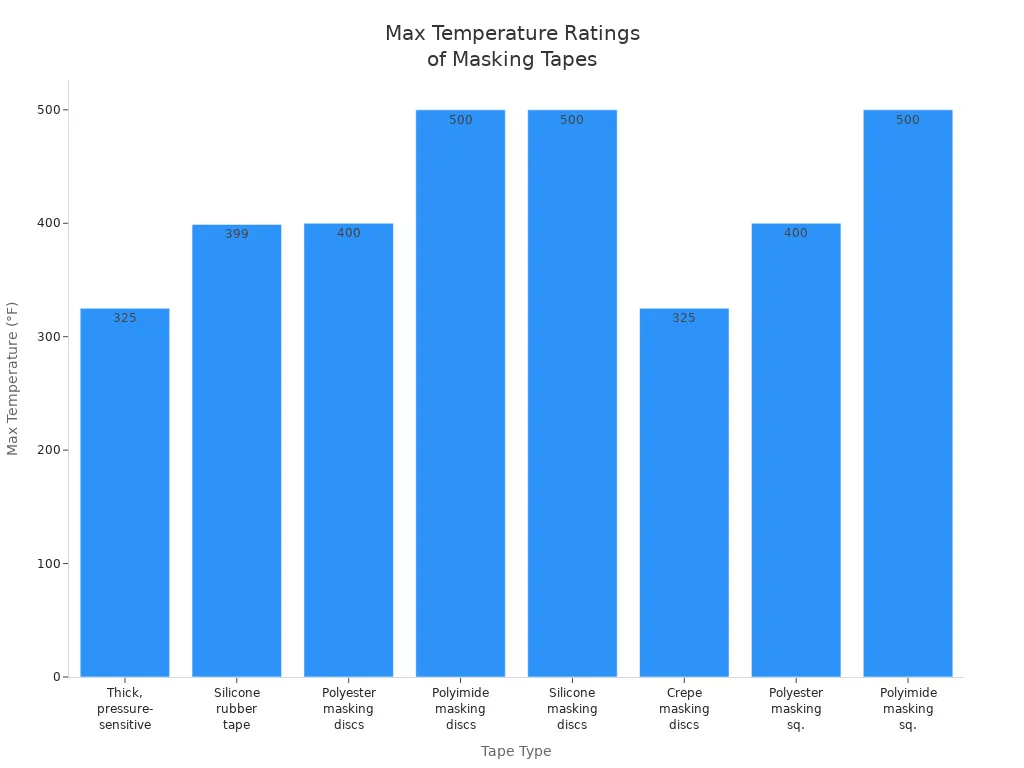

When you pick a high temperature masking tape, you want it to stand up to the heat. The best tapes for 2025 can handle some serious temperatures. Take a look at this table to see how different types compare:

Tape Type | Maximum Temperature Rating |

|---|---|

Polyimide Tapes | -269°C to 400°C |

Aluminum Foil Tapes | Up to 600°F (316°C) |

Silicone Tapes | Up to 500°F |

You can see that some tapes, like aluminum foil and polyimide, work in extreme heat. Brands like 3M even offer heat resistant tape that goes up to 600ºF. If you need to mask parts for powder coating or soldering, these tapes will not let you down.

Adhesive Performance

You want a tape that sticks when you need it and peels off cleanly when you’re done. The top tapes use advanced adhesives that hold tight, even when things get hot. Many users in 2025 say these tapes leave no sticky mess behind. You get sharp paint lines and no residue, which saves you time on cleanup. New adhesive technology also means you can use these tapes on lots of surfaces, from metal to plastic.

Application Versatility

You can use these tapes for more than just one job. They work in automotive shops, electronics factories, and even for crafts at home. Here’s why so many people choose them:

The market for masking tapes is growing fast, with more people using them for cars, home projects, and construction.

Many buyers now look for eco-friendly options, and brands are responding with greener materials.

New adhesive formulas and better production methods make these tapes easier to use and more reliable.

Tip: If you want a tape that works for many projects, choose one with a wide temperature range and strong adhesive.

You can trust these tapes to handle almost any job. That’s why they lead the market in 2025.

High Temperature Masking Tape Product Reviews

Overview

When you look for the right high temperature masking tape, you want something that stands up to heat and makes your job easier. The best tapes keep their shape, stick well, and come off clean. You can use them in places like car shops, factories, or even at home. Here are some important things to check before you pick a tape:

Factor | Description |

|---|---|

Ability to tolerate high temperatures | Keeps the tape strong in hot jobs like automotive or electronics work. |

Easy Removability | Lets you peel the tape off without leaving a mess or damaging your project. |

Clean and effortless tearing | Saves you time and helps you get a neat finish. |

Cost-Effective | Helps you stay on budget for big or small projects. |

Pros and Cons

Every tape has good points and some drawbacks. Here’s what you might notice when you use these tapes:

Pros | Cons |

|---|---|

Sticks well to metal, glass, and plastic | May not stick to some surfaces like Teflon |

Leaves little or no residue after heating | Can leave residue if the surface is dirty |

Works for many heat levels | May fail if you stretch it too much |

Meets safety standards | Can lose strength under heavy stress |

Tip: Always clean your surface before you apply the tape. This helps you get the best results.

Ideal Uses

You can use high temperature masking tape for many jobs. Here are some ideas:

Masking car parts before painting or powder coating

Protecting circuit boards during soldering

Holding transfers in place for heat press crafts

Covering metal or glass in industrial ovens

If you work with heat, you will find a tape that fits your needs.

Unique Features

Some tapes offer special features that make your work easier. You might find tapes that:

Tear by hand for quick use

Use eco-friendly or recycled materials

Resist chemicals and abrasion

Come in bright colors for easy spotting

You can pick a tape with the features that matter most to you. With so many choices, you will find the perfect fit for your next project.

Buying Guide

Choosing the right high temperature masking tape can feel tricky, but you can make it simple by focusing on a few key factors. Let’s break down what you need to look for.

Temperature Range

First, check the temperature range. You want a tape that can handle the heat of your project. Some tapes work for light jobs, while others stand up to extreme temperatures. Here’s a quick look at how different tapes compare:

Type of Tape | Maximum Temperature |

|---|---|

Thick, pressure-sensitive | up to 325°F (163°C) |

Silicone rubber tape | up to 399°F (204°C) |

Polyester masking discs | up to 400°F (204°C) |

Polyimide masking discs | up to 500°F (260°C) |

Silicone masking discs | up to 500°F (260°C) |

Crepe masking discs | up to 325°F (163°C) |

Polyester masking squares | up to 400°F (204°C) |

Polyimide masking squares | up to 500°F (260°C) |

Tip: Always match the tape’s max temperature to your project’s highest heat.

Adhesive Type

Next, think about the adhesive. The right adhesive keeps your tape in place and peels off cleanly. Here’s a quick guide:

Characteristics | Cost | Applications | ||

|---|---|---|---|---|

Silicone | Flexible, resists aging and UV | High | Expensive | Splicing, masking, polyimide tapes |

Acrylic | Good adhesion, resists aging | Moderate | Moderate | Fiberoptic, general use |

Rubber | Strong tack, less UV resistance | Low | Low | Duct, low-temp masking |

Silicone adhesives work best for high heat. Rubber adhesives cost less but don’t handle high temperatures as well.

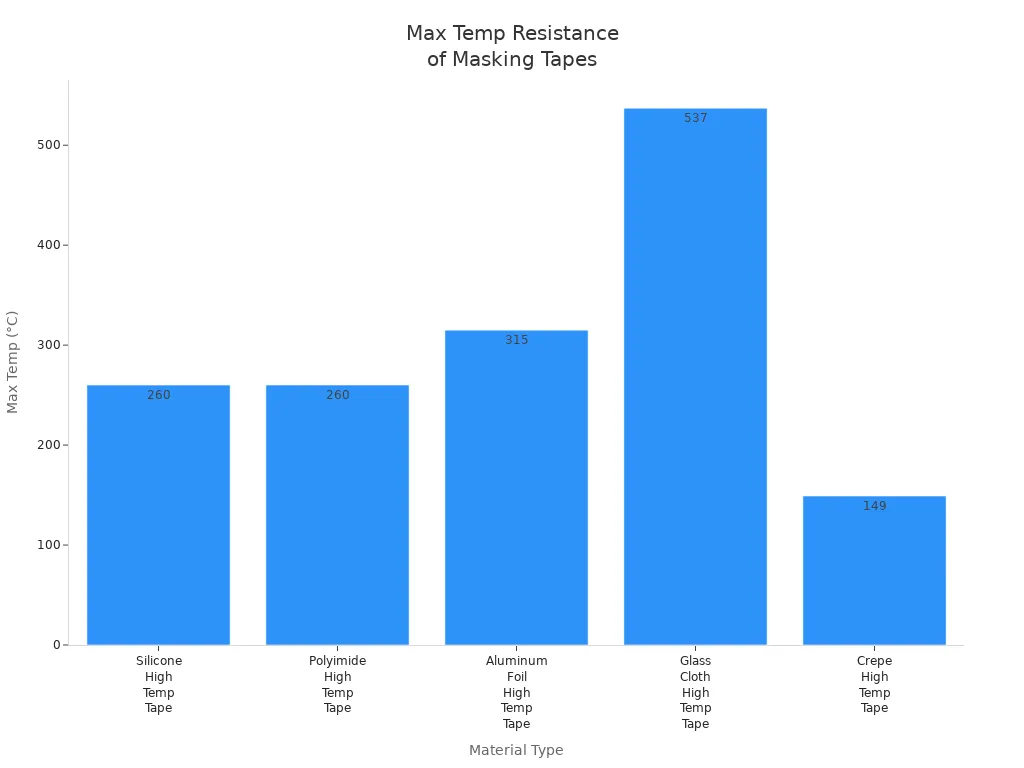

Material

The tape’s material affects how it performs. Some materials handle heat better, while others offer more strength or flexibility.

Material Type | Temperature Resistance | Key Properties |

|---|---|---|

Silicone High Temperature Tape | Up to 500°F (260°C) | Great for electrical insulation and soldering. |

Polyimide High Temperature Tape | Up to 500°F (260°C) | Perfect for painting in aerospace and automotive. |

Aluminum Foil High Temperature Tape | Up to 600°F (315°C) | Used for HVAC and ductwork. |

Glass Cloth High Temperature Tape | Up to 1000°F (537°C) | Strong and abrasion-resistant, ideal for welding. |

Crepe High Temperature Tape | Up to 300°F (149°C) | Good for automotive painting. |

Polyimide and silicone tapes are your best bet for most high-heat jobs.

Application Method

How you use the tape matters, too. For the best results, follow these steps:

Clean the area before you stick the tape.

Press the tape down firmly.

Peel the tape away slowly after heating.

Pick a tape rated for your job, like powder coating or soldering.

A clean surface and firm pressure help the tape stick better and come off without a mess.

With these tips, you can pick the perfect high temperature masking tape for any project!

Selection Methodology

Choosing the best high temperature masking tapes for 2025 takes more than just picking popular brands. You want to know how these tapes made the list. Let’s walk through the process so you can trust your choice.

Criteria

You need to look at more than just heat resistance. Here’s a table showing what matters most when picking top tapes:

Criteria | Description |

|---|---|

Product Quality & Consistency | Does the tape stick well, resist heat, and leave no residue? Is it reliable every time? |

Innovation & Technology | Does the tape use new materials or coatings for better performance? |

Customization Options | Can you get the tape in special sizes or for unique jobs? |

Supply Chain Reliability | Will the tape arrive on time? Does the company ship worldwide? |

Pricing & Cost-effectiveness | Do you get good value for your money? |

Customer Support & Technical Help | Can you get help fast if you have a problem? |

Environmental & Safety Standards | Does the tape meet safety and eco-friendly rules? |

Global Presence & Scalability | Can the company handle big orders in many countries? |

Tip: Always check if the tape meets safety and environmental standards before you buy.

Evaluation Process

You want to know how each tape was tested and ranked. Here’s how the process works:

Criteria | Description |

|---|---|

Heat Resistance | Can the tape handle high temperatures without failing? |

Adhesion Strength | Does it stick during use and peel off cleanly? |

Durability & Flexibility | Will it resist tearing or cracking? |

Ease of Use | Is it simple to apply and remove? |

Chemical Compatibility | Can it handle paints, solvents, or other chemicals? |

Compliance & Certifications | Does it meet industry standards like ASTM or ISO? |

Price & Availability | Is it affordable and easy to find? |

Customer Support & Validation | Does the company help you solve problems quickly? |

You want a tape that scores high in all these areas.

Data Sources

To make sure you get the best advice, we used many sources:

In-house testing and research

Market studies and industry reports

Reviews from real users and experts

Social media trends and feedback

Interviews with industry professionals

Scientific journals and technical publications

Data from national and international associations

Note: We also looked at how new technology, changing prices, and global events affect tape quality and supply.

With this careful process, you can feel confident choosing any tape from our top seven list.

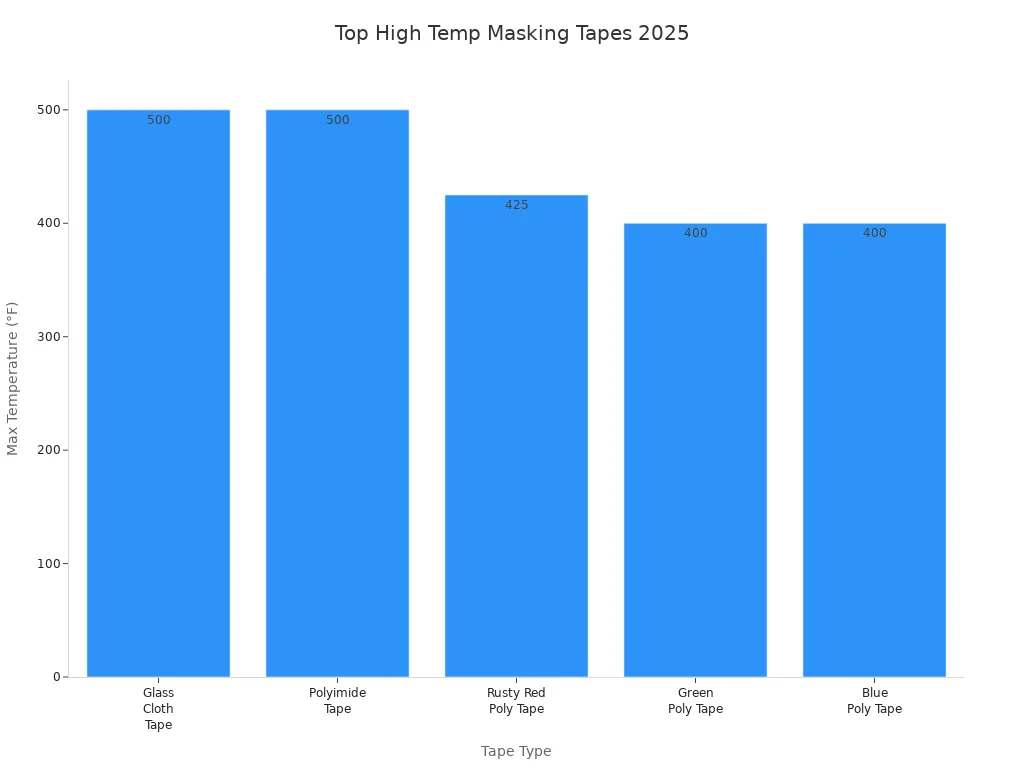

You have many great options for high temperature masking tape in 2025. Each tape stands out for its heat resistance, clean removal, and special features. Check out this quick table:

Tape Type | Temp Rating | Key Features |

|---|---|---|

Glass Cloth Tape | 500°F | Flame retardant, strong for thick coatings |

Polyimide Tape | 500°F | Clean removal, long high-temp cures |

Rusty Red Poly Tape | 425°F | Budget-friendly, moderate heat jobs |

Green Poly Tape | 400°F | Industry standard, powder coating |

Blue Poly Tape | 400°F | Flexible, fits uneven surfaces |

When you pick a tape, think about what your project needs. Look for strong adhesion, easy removal, and the right color for visibility. Always match the tape to your job, whether you need strength, flexibility, or chemical resistance. Brand reputation, application, and budget matter, too. The right choice keeps your project safe and your costs down.

FAQ

What makes a masking tape “high temperature”?

High temperature masking tape can handle heat without melting or losing stickiness. You can use it in ovens, during soldering, or for powder coating. Regular tape will not work for these jobs.

Can I use high temperature masking tape for crafts at home?

Yes! You can use it for heat press projects, iron-on transfers, or even baking. It peels off cleanly and does not leave a sticky mess.

How do I remove high temperature masking tape without leaving residue?

Let the tape cool before peeling. Pull it back slowly at a low angle. If you clean the surface first, you get the best results.

Is high temperature masking tape safe for electronics?

You can use many high temperature tapes on circuit boards and wires. Look for tapes labeled “electrical insulation” or “polyimide” for extra safety.

How do I choose the right tape for my project?

Tip: Match the tape’s temperature rating to your job. Check the adhesive type and material. If you need help, ask the supplier for advice.

English

English  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  čeština

čeština  Polska

Polska  Svenska

Svenska  magyar

magyar  Nederland

Nederland